Review

of Taurus

627

627SS Tracker and Accessories

Revision 1.2

I had a chance to use a Taurus

model 627SS Tracker chambered for .357 / .38 Special with a 4" barrel. Some have said the .357

Magnum / .38 Special is the best overall revolver to own. I also used speedloaders from HKS 587A and 5-star

Firearms 7L-357/38, and Tuff

8357 Quickstrips. I also was provided a Wilderness

Speedloader Carrier. Lastly, I used a 4" revolver holster

by Federal. This page reports my observations.

A sister page documents how to clean lead out of a barrel

after shooting 300 rounds of lead round-nose bullets. Unlike most

autoloaders, revolvers will work even when they are very dirty.

That said, a Sig P239 shot over 600 rounds without a cleaning and never

glitched once.

Looking at the bottom of the speed loader,

you can

see the shaft and roll pin that flips flops to either side of a ball

bearing under spring pressure. The rotating center shaft is in

the CW position as shown in the picture. When in the CCW position

(as viewed from the top), little star corners stick out into the

cylinder holes to hold the casings.

Interesting, all of the cartridges did not fit! The Armscor FMJ

.357

dropped in fine. The Hornady XTP .38 Special dropped in

fine. The

Magtech LRN .38 Special did not fit. I could push it in, but it

absolutely would not drop out. As shown in the picture, two

cartridges are dropped in the holes, while the LRN catridge is balanced

on the hole, and won't drop in. You can't use this speed loader

with this cartridge.

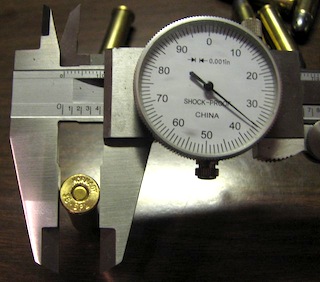

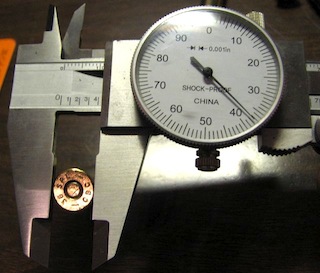

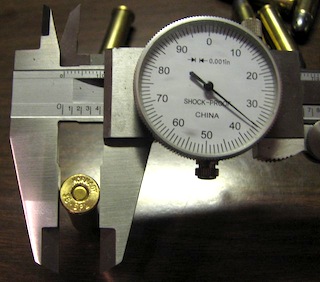

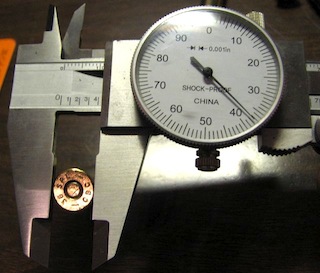

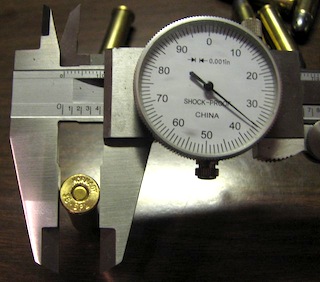

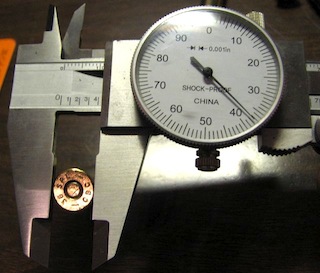

I got out my calipers and micrometer and

checked a few things. Cartridge body spec'd diameter is

0.379". Spec size for the rim is

0.440". Diameters in increasing rim size order are:

All the cartridges are smaller than spec,

so they all should have fit into the larger speedloader hole. I

was intrigued why the Magtech .38 Special LRN catridge would not fit into the

bigger hole. It turns out the "round" holes of the speedloader

are not quite round. The holes are a little bit

"dog house" shaped, which gave a loose fit only to cartridges

significantly smaller than hole size. I think this is a character

of the HKS 7-cartridge reloaders; the walls between the holes are just

so thin, the black plastic slightly deforms.

I received model L7-357/38. These

run about 2-3x the cost of the HKS speedloaders. The 5-star

loaders

are milled from solid Aluminum blocks. Notice the backside of the

speedloader is solid, and there are no walls of metal

between the cartridges like the HKS speedloader. The lack of

walls between cartridge slots makes this speedloader workable with all

cartridge types I have.

So far, I don't like the "hexbolt" knob on the back side of the

5-star, believing the knurled knob surface of the HKS gives a better

grip. With the aluminum construction, 5-Star

is able to paint or anodize loaders in various colors. They even

offer one anodized in light green with red accent paint for their

"zombie apocolypse speed loader". It seems they're just starting

to experiment with the colored concept and have not matured the product

line. Different anodized colors would be perfect for different

calibers or bullet types. For instance, maybe round nose

in blue loaders, and hollow point in red loaders. Or for the

caliber I'm working with, it would be great to have two colors - one

loaded with .38 Special and one loaded with .357 Mag. My wife

would grab one color, I'd grab the other. For all the

success Apple found doing this with MP3 players, I think 5-Star has

room to expand their line.

The HKS loader has metal retention pins or star that press the

bullets

back against the outer side of the cartridge holes. The 5-star loader

has a similar design except the metal retention star does not apply any

radial pressure to the cartridge. It just swings into place and

prevents the rim from falling out. The result is that the HKS is

quieter and less "wiggly". The 5-star makes more rattly noise when

wiggled, but lets the cartridges fall out freer when released. When

secured in the loader carrier, the 5-star loader definitely rattles

with each step. The HKS loader is silent. The

5-star speedloader also easily handles the Magtech .38 special LRN

cartridges that were too snug of a fit in the HKS loader.

Lastly, something I did not expect, the HKS releases the cartridges

when the back knob is rotated clockwise. The 5-star loader

releases cartridges when the back knob is rotated counter-clockwise.

Uggh.. that bothered me a bit. When situations get moving

quickly, I want to have muscle habits down always doing things the same

way. For know, in the dark, if I feel knurling, I rotate

CW. If I feel a hex knob, I rotate CCW. Not ideal.

The best. It's sewn together in sort of a cross shape. Side

straps come around the speedloader from either side and secure down

with hook-n-pile fasters. Any diameter speedloader would fit. The

top drops over the loader and is secured on the front. A good

design I didn't expect is the secondary strap that goes down the back

inside of the carrier and hooks across the bottom. This is a good

way of securing the entire assembly onto your belt without a hook and

without threading your belt through a sewn loop. When I took the

picture shown here, I tried to disconnect and set the belt strap a

little bit crooked so you can see it in the picture.

I usually keep one or two of these on my belt-line and any other

reloaders in a pocket or pouch the way an auto user would put some

magazines on the belt and some in pockets. I use the speed

loaders in my pockets first and retain the belt-mounted ones for last

or for when the fastest swap time is required.

These

proved to be WAY more useful than I imagined. The cylindrical speed

loaders are good only for initial loads or "emergency" reloads when

you've depleted the cylinder and need to respond quickly (animal or

human aggressor is still coming, possibly shooting at you). Get

under cover and reload quickly by dumping all empties and put in 7 new

bullets.

When running through some house clearing exercises, I ealized when there's a pause or the engagement is on my

timeline, typically only part of the bullets were shot and there was no

way I wanted to dump good bullets. Instead I opened the cylinder

and flicked out 2-4 bullets - which are always from the same locations

in the cylinder of course, so this can be done even in the dark.

Then I pulled the quick strip from a rear pocket, reaching over the top

of the gun. I could put 2 bullets at a time as fast as the auto

guys could rotate a topped-off clip into their handgun. In

practice drills using 2-4 bullets, I could top off and be back in my

holster faster than the auto magazine swappers. Massad Ayoob demo.

In other words, emergency reloads => use the cylindrical

reloaders, tactical reloads => use the quick strips. See

also Quickstrip Loading Drills.

The gun alone weighs in at 37 oz. Taurus' web page

says it weight 28.8 oz, which is not true for the stainless steel

model. I think the published weight is for a titanium

version. Trigger pull DA is 12

lbs, and the trigger pull SA is 5 lb. DA trigger travel is 1.4

cm. Firing the gun with the hammer cocked back is very smooth and

requires less than 1 mm of trigger movement.

Using only the FMJ .357 cartridges, I

practiced loading cartridges using an

HKS 587A speed loader. Drop the cartridges into the holes, and

rotate the metal knob counterclockwise. Rotating the knob

clockwise drops them all out. I spent one night doing this over and

over again, practicing until I could do it quickly in the dark.

Click on the photo to watch the Quicktime

video.

After about 50-100 practice load cycles, I pushed

the cylinder closed, and it wouldn't close. It pretty much locked

up! No gun should do this. Especially a "reliable"

revolver. Especially a brand-new 4-day old revolver that had

never been used. I forced the cylinder open, and removed the

cartridges. The mechanisms remained stuck, and the gun became

non-operational. In a real-life live-or-die situation, I could not have

fired a cartridge in any way! Ouch!! Click on the photo

to watch the Quicktime video.

After about 50-100 practice load cycles, I pushed

the cylinder closed, and it wouldn't close. It pretty much locked

up! No gun should do this. Especially a "reliable"

revolver. Especially a brand-new 4-day old revolver that had

never been used. I forced the cylinder open, and removed the

cartridges. The mechanisms remained stuck, and the gun became

non-operational. In a real-life live-or-die situation, I could not have

fired a cartridge in any way! Ouch!! Click on the photo

to watch the Quicktime video.

What you see in this video: Release

seems to be properly forward. Cylinder close is tight.

Hammer won't cock back. Trigger won't pull. Cylinder

release did not click back (still sprung forward). Forcing cylinder

open and closed again fixed the release. Hammer is still unable

to pull back. Trigger still won't fire the gun.

Fiddling with the trigger, cylinder

release, hammer, and cylinder got it to lock up in various modes.

In this case, the triger stuck back. Click on the photo to watch the

Quicktime video.

What you see in this video: Notice trigger

is stuck back to start with, with nobody touching the gun.

Cylinder release will not operate. Cylinder will not rotate. Trigger

does nothing (it's already stuck back). Hammer does cock and seems to

release, but then hammer won't come back again, and trigger won't work.

Can you imagine this happening when the bad guy is

approaching? Double thumb jamming the cylinder release causes it

to work. Hammer and trigger still non-operational.

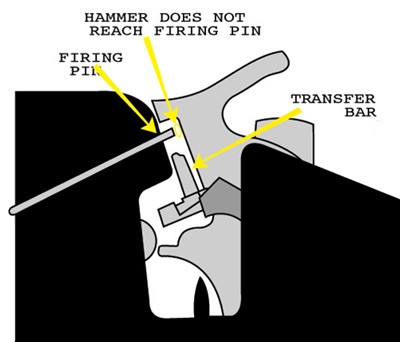

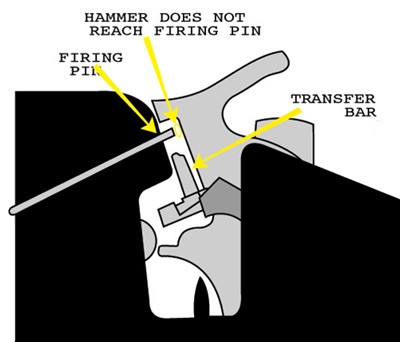

Also, amidst all of this, I noticed the transfer bar,

which is suppose to block the firing pin from the hammer, can be

depressed (along with the firing pin) no matter what position the

trigger is in. Taurus

product specification

says, "The transfer bar mechanism prevents the hammer from striking the

firing pin unless the trigger is pulled fully to the rear." I'll have

to investigate this more.

Also, amidst all of this, I noticed the transfer bar,

which is suppose to block the firing pin from the hammer, can be

depressed (along with the firing pin) no matter what position the

trigger is in. Taurus

product specification

says, "The transfer bar mechanism prevents the hammer from striking the

firing pin unless the trigger is pulled fully to the rear." I'll have

to investigate this more.

Taurus does offer a lifetime

warranty. Handguns have to be sent FedEx or

UPS overnight by air. That's a $100.49 bill one-way. With a

brand new gun, Taurus may cover the cost both ways. I agree with Chuck Hawks

#1 rule for a home defense weapon: 100% reliability,

so I'm concerned about the viability of the gun for this purpose. I

will start gaining back confidence after putting several hundred rounds

through

it, with a burst of no less than 100, to see how it behaves with a hot

barrel. Guns

are survival tools, and must be meet high standards of

trustworthiness.

The holster is just the right size for the 4" Taurus

Tracker. It's

made with a tough grade of synthetic fabric, and has padding sewn into

the fabric. It provides for an easy firm handle grip, thumb button

release, and quick draw. Like any thumb release holster, putting the

revolver back is probably a two-handed effort to secure the button. The

belt clip is easy on/off, but is a bit more loose that threading your

belt through the sewn on loop. The thumb release strap is

hook-n-pile

secured on both ends, so it is adjustable back and forth to where you

like it.

Stitching around the edge of the holster seems to be a 2-pass

affair.

The second pass has really loose stitching. Look at the picture

below near the bottom round part. It's almost as if the

sewer ran out of thread while making this holster and started the next

spool by double stitching for a few inches. I'll update text here

after the holster wears for a while.

I couldn't find the manufacturer website, so the link above is to the

Amazon store. The holster arrived in a plastic bag with what

looked

like a UPC label "X0002BKODL" with the words '4" Revolver Holster

S&W 27, 29, 629, 686, Ruger Redhawk'. However, the ASIN and

Model

number on the Amazon page don't match.

Loaded with .38 Special LRN bullets, the gun and holster weigh in at

43 oz. Notice this conflicts with the 28.8 oz empty weight claimed for

the model 627 on on Tarus' website. The weight is enough to pull the

belt down a bit, but when I get working,

I forget it's there. Size is fine for working around the garage

or

sitting at a desk. With a pair of jeans, I wear it behind the

side

belt loop of the pants, putting it a bit aft of a direct

side-carry. For a weight comparison, my classic (old) Leatherman

Super

Tool with carrying pouch weighs in at 10 oz. Although the weight of the

handgun package is 4x, the size and shape makes it feel maybe twice as

"pull down-y" as the leatherman.

After about 50-100 practice load cycles, I pushed

the cylinder closed, and it wouldn't close. It pretty much locked

up! No gun should do this. Especially a "reliable"

revolver. Especially a brand-new 4-day old revolver that had

never been used. I forced the cylinder open, and removed the

cartridges. The mechanisms remained stuck, and the gun became

non-operational. In a real-life live-or-die situation, I could not have

fired a cartridge in any way! Ouch!! Click on the photo

to watch the Quicktime video.

After about 50-100 practice load cycles, I pushed

the cylinder closed, and it wouldn't close. It pretty much locked

up! No gun should do this. Especially a "reliable"

revolver. Especially a brand-new 4-day old revolver that had

never been used. I forced the cylinder open, and removed the

cartridges. The mechanisms remained stuck, and the gun became

non-operational. In a real-life live-or-die situation, I could not have

fired a cartridge in any way! Ouch!! Click on the photo

to watch the Quicktime video. Also, amidst all of this, I noticed the transfer bar,

which is suppose to block the firing pin from the hammer, can be

depressed (along with the firing pin) no matter what position the

trigger is in. Taurus

product specification

says, "The transfer bar mechanism prevents the hammer from striking the

firing pin unless the trigger is pulled fully to the rear." I'll have

to investigate this more.

Also, amidst all of this, I noticed the transfer bar,

which is suppose to block the firing pin from the hammer, can be

depressed (along with the firing pin) no matter what position the

trigger is in. Taurus

product specification

says, "The transfer bar mechanism prevents the hammer from striking the

firing pin unless the trigger is pulled fully to the rear." I'll have

to investigate this more.