I had a chance to spend some range time

with a Taurus

model 627SS Tracker chambered for .357

Magnum / .38 Special, 4" barrel, shooting Prvi Partizan

(PPU) 158 gr (10.2 gram) Lead Round Nose (LRN) 38 Special

bullets. I previously posted a review of

the Taurus 627SS and loader accessories. On this trip, I was

interested in how the gun would perform with lead bullets and wanted to

know what failure mode would show up first. I want to be

confident in self-defense situations, but also might trust this gun in

the field against larger wild animals where it's not kept in perfect

condition.

I shot about 300 rounds over 3 days and

the only cleaning I did was to wipe down the front sight with alcohol

or water to remove the smokey smudge that builds up after about 80

rounds. Alcohol pads are great to remove the soot

collection.

Licking your finger to wipe soot away works less well, and probably

introduces lead into your body. Half way

through the third day, instead of shooting with a free hand double

action accuracy of about 5 minutes of arc (MOA), the bullets started

dropping about 8 cm over 15 yards. Precision was still holding,

but all the bullets were curving low about 8 cm on target.

Adjusting the sights

didn't change the impact point, and that made me really suspicious

because the only way that could happen is if the bullets were being

lobbed out of the barrel at a very slow speed. If you do a gravity calculation, you can

see that a bullet falls about 8 cm in 0.128 seconds. Because I

was 15 yards (45 feet) away creating the 8 cm drop, that means the

bullet was traveling 45 feet in 0.128 seconds or 350 fps. They're

specified by the manufacturer at 890 fps, but they were coming out of

the barrel at 350 fps - a 60% loss in velocity! That means the

barrel was really clogged, and I'm lucky it was a barrel meant to

handle 357 pressures while I was shooting only 38 specials!

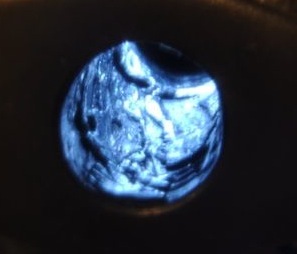

The first two photos show what I found back home, looking down the front of the barrel, back illuminated with a LED illuminator. Looks like pictures of cholesterol plugged arteries! The lead was pretty much untouched after running a brash brush about 50 strokes and trying three different bore cleaners. Looking at the cleaners I used, they all indicated they would remove copper. Yup, I guess so. But not lead!

The third photo is the finished barrel after about three hours of work including dissolving lead into liquid mercury and hundreds of strokes with pure copper abrasive. If you can see two scratches, it's because I first tried to (and failed to) poke the lead chunks out with a screwdriver. Resolution/focus of the pictures is the best I can do without a macro lens on my camera.

| BEFORE |

BEFORE | AFTER |

|

|

|

Below are the tools I used. Towel covers the work surface.

Red flashlight with LED on the end of a flexible shaft illuminates the bore interior. Chore

Boy dish cleaning abrasives ($1.21 after tax) were unfolded (they're

normally folded in

on themselves to keep them a ball), magnifying glass, dental spoon,

biological disection poker, chemistry spatula, bore cleaning rod with

copper filaments pushed through the end loop.

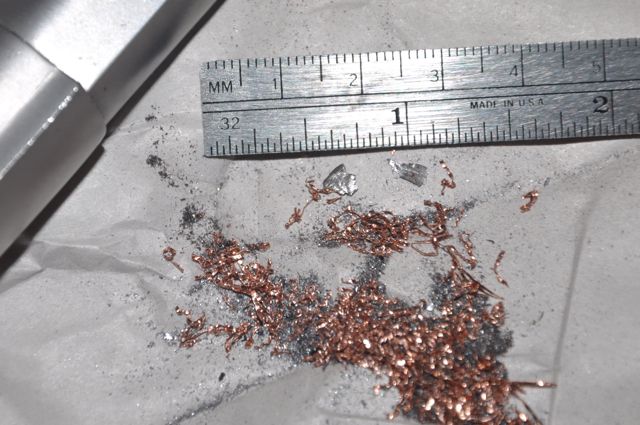

Photo below shows what about 75 strokes

of copper strands accomplished. Clearly a pile of lead started to

accumulate on the towel. This would work, but would take a long

time. This is similar to the Lewis

Lead Remover toolkit that uses brass weaved disks instead of copper filaments. Others recommend wrapping the copper

filaments strands around a normal brash brush.

You can read several places on the web

about using hydrogen peroxide and vinegar to form a chemical complex

with the lead and create Pb2(CH3COO)2

(lead (II) acetate), possibly lead (IV) acetate (need to research this

a bit more). Most of the lead will dissolve into the liquid

solution you but into the barrel and the rest can be wiped off the

barrel with a cleaning patch after you remove the liquid. Lead

acetate is water soluble, so this can gets into your system

easily and even through your skin. Realize that because there is

probably already lead residue on your hands, just getting the

peroxide/vinegar solution onto your hands will do the same reaction and

create the lead acetate solution right on your skin. Although it used to be a medicinal

drug, we now know lead acetate

is toxic.

If clean your barrel with this method, you'll have toxic solution coming out and toxic crud on your barrel

wipes. If you there is a company using chemicals or a college nearby, ask to speak with

their lab manager and ask if you can add your liquid to their liquid

inorganic waste collection. They probably have a waste

stream for the used cleaning patches, too.

You can lower some of the threat of

lead acetate

solution by putting it into a strong liquid acid to push the hydrogen

back on

the acetate and make acetic

acid (vinegar or film camera fixing agent) and a lead precipitate. The toxic problem

is

the lead part of the equation. The lead turns into lead chloride

if you use hydrochloric acid or lead sulfate

if you use sulfuric acid (battery acid). Both of these new lead

compounds are also toxic (see MSDS lead

sulfate, lead chloride).

However, unlike lead acetate, they are insoluble in water, so they

precipitate out of

water so you can filter it and dispose of it easier than the lead

acetate. These precipitation reactions are some of the

"qualitative analysis" chemical reactions freshman college students

learn.

For perspective, lead sulfate is the white powder that forms on your car

battery lead terminals,

so you have probably dealt with it before, blown it away with an air

compressor hose, or washed it away with the hose down the

driveway. No, you

should not do this. You'll probably get

Parkinson's disease if you continue being careless. Notice that car

mechanics are now do work with latex gloves, unlike the old day.

I have some liquid

mercury I've been trying to get rid of or find a use for, so I decided

to try that method. BTW, if you want to try this, I have lots of

extra mercury and I'd be happy to sell you small quantities. If

you have a clear lab bench to work and understand how to work around

chemicals, it can be a safe, quick, and thoroughly removing lead.

Federal law requires only 1 pound maximum can be shipped between

private parties, and it needs to be done via FedEx - USPS and UPS won't

do it.

Notice in the picture below, the mercury

is shiny and has a high surface tension (tends to puddle up easily and

won't wet the container it's in). After reacting with the lead it

will be different. I have the tip of a little suction bulb

showing on the right side of the picture, but don't plan to move

mercury that way. It doesn't pick up well because it's so

heavy. That is one of the reasons mercury protocol is to always

have a non-metallic catch basin under your work so that you catch any

spills and can lift the mercury back up and pour it into a storage

container.

As shown below, I used electrician's tape to plug the front and side vents. Next time I would try to find something that the mercury/lead didn't stick to. (Next time I may experiment with foam ear plugs. I'm not sure if that would block the mercury or allow it to get into all the little foam holes.) After sealing off the front of the gun barrel, I poured the mercury from the film canister into the gun barrel. Lastly, I sealed the chamber with another piece of tape. Shake. Tilt around. Tip back and forth. Agitate. Basically move the mercury around to react with the lead in the barrel.